Jointing

Procedures For Pipe Installation Are States In DIN 1963. DIN 18300 And EN 1610 Standards Pipes May Be Lowered To The Canel After Being Welded Outside The Canal. Keeping Canal Excavation Narrow Is The Important Matter In Here.

Procedures For Pipe Installation Are States In DIN 1963. DIN 18300 And EN 1610 Standards Pipes May Be Lowered To The Canel After Being Welded Outside The Canal. Keeping Canal Excavation Narrow Is The Important Matter In Here.- Pipes Must Not Be Crushed In No Matter.

- Usage Of Pipes Damaged During Stocking Or Transportation (Damaged By Sharp Tools Or Maternal Like Stone) Must Be Strictly Avoided.

- The Must Not Be Any Accumulation Of Subterranean Water Or Rain Water In The Canal (In Case Of Presence Of Water In Canal, It Must Be Discharged By Pumps) Non-Sticking Sand, Pebble, Mixed Sand With Mixed Grain And Pebble Are Suitable For Use As Filling Material (DIN 19630 Standard)

- Canal Depth Must Be Of Minimum 70-80-Cm

- If The Excavation Soil Is Suitable For Filling. Pipe May Be Laid On Bottom Of Canal Without Need For Bedding. If The Excavation Soil Is Not Suitable (Stony, Moist, Etc.) For Filling, Canal Depth Must Be Increased And Bedding With Dry Filling Material (E.G. Sand) Must Be Applied.

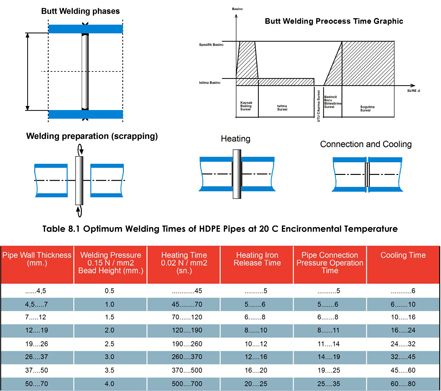

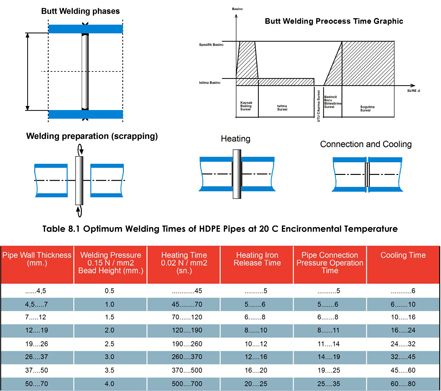

HDPE Butt fusion Jointing Procedure

Prior to welding process, welding surfaces must be scrapped, oxidation removed and complete contact of welding surfaces must be provided.

Prior to welding process, welding surfaces must be scrapped, oxidation removed and complete contact of welding surfaces must be provided.- After scrapping of the welding surface it must be preserved from dirt. If there is any re dirtying, the scrapping process must be repeated.

- Prior to being heated with iron, the surface to be welded must be cleanse with pure alcohol.

- Although the weld iron heat is between 200°C – 220°C. It must be designated regarding the raw material of the pipe and application standard.

- After the weld process has started during weld cooling period the connection pressure values of the pipes must be kept equal.

- Since, the air circulation formed in the pipes accelerates the cooling process of weld, during welding one end of the pipes must be closed.

- Before starting welding process the heat values of the machine must be checked and welding must be started 5 minutes after reaching desired heat value.

- Iron part of the machine and the welding part of the pipe must be cleaned prior to welding.

- Welding pressure test for pressurized drinking water pipes are applied in accordance with EN 805 standard.

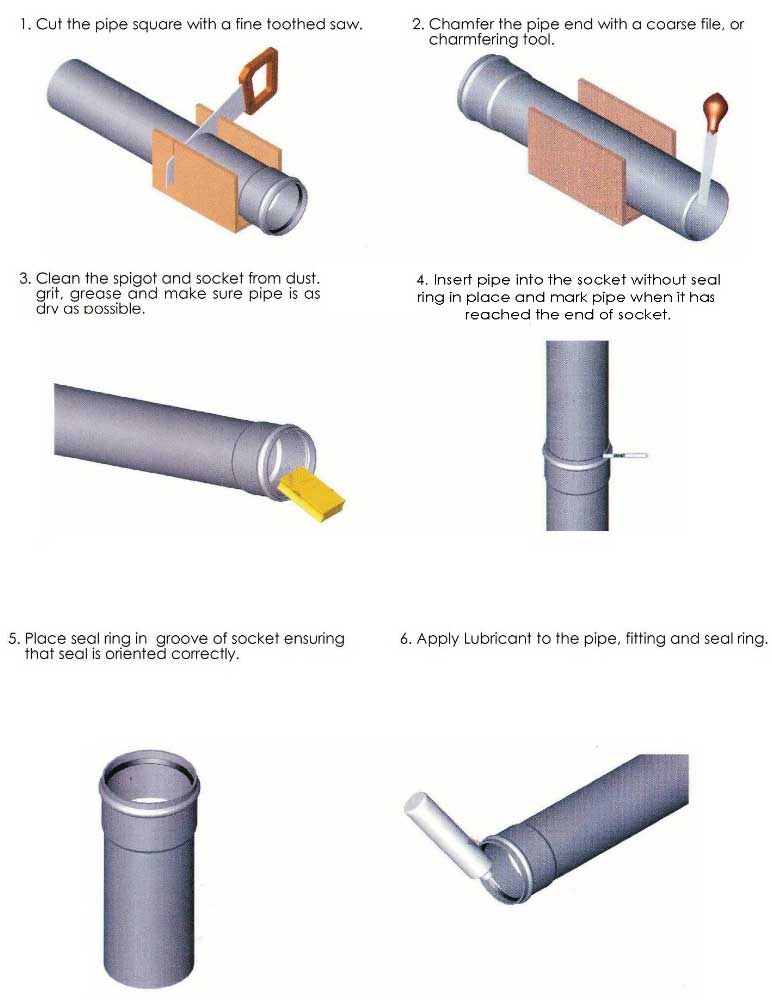

uPVC BS Pressure Pipe Joining Method

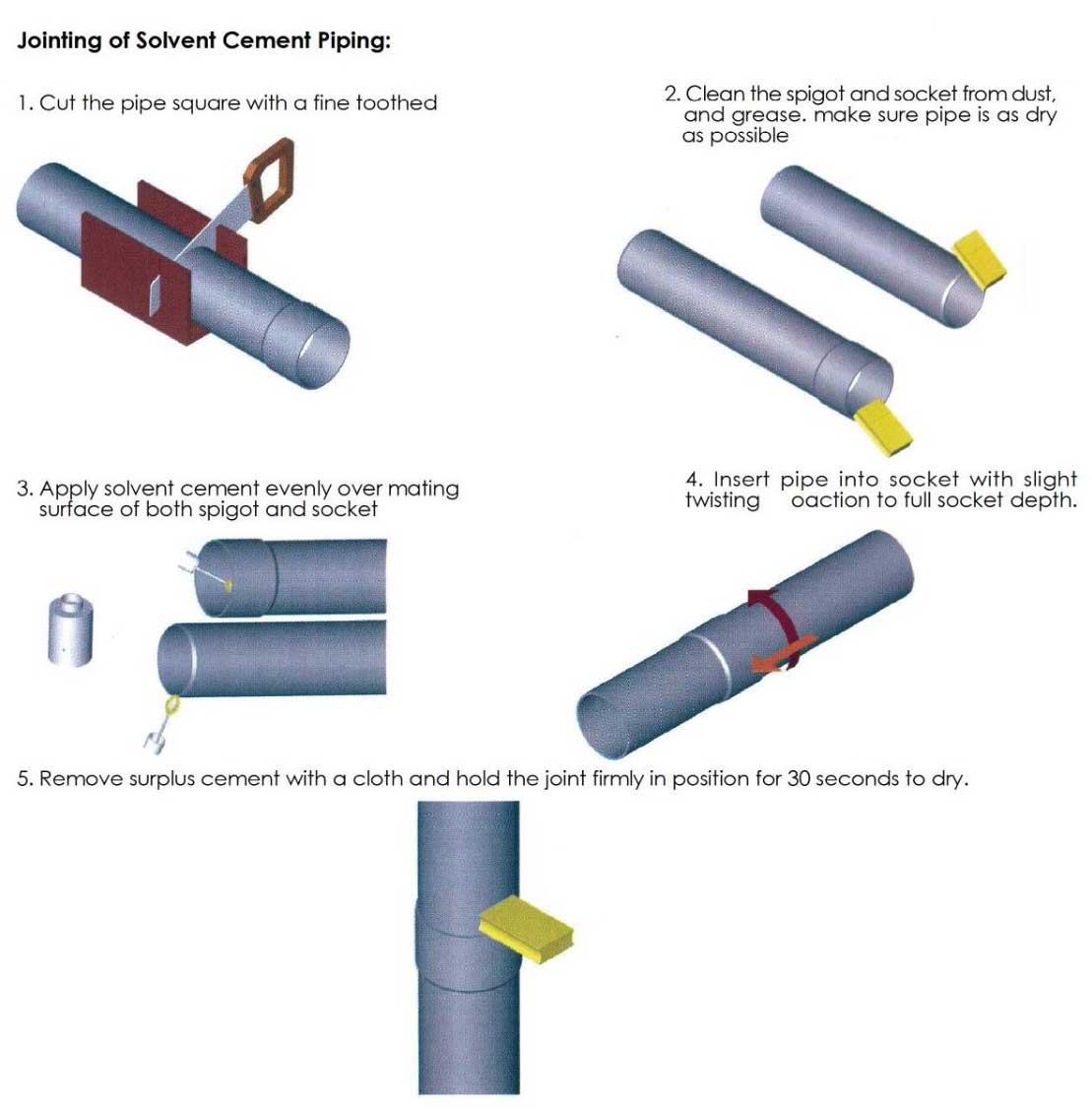

uPVC BS Pressure Pipe Jointing Method 2

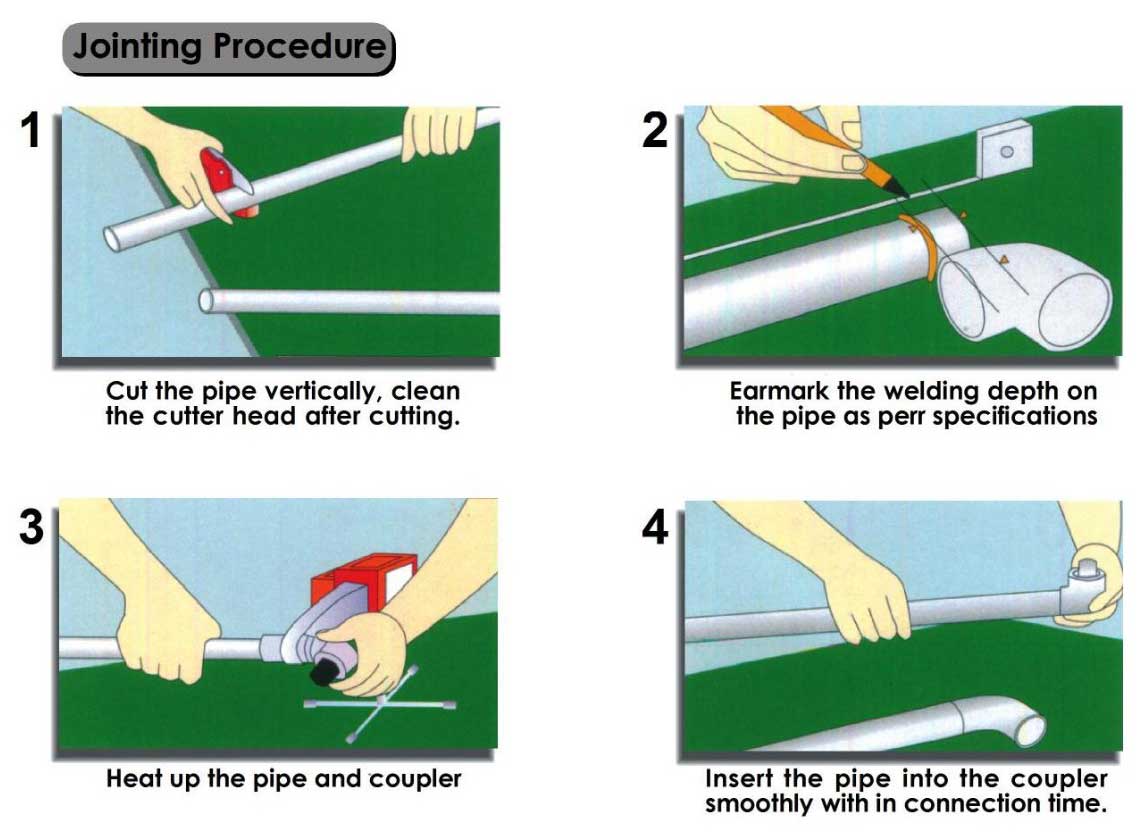

PPRC Jointing Method

There must be no nails, hard substances, stone, etc. in the dump box of the transporting vehicle.

Pipes must not be placed in the vehicle in disorder.

Pipes must never be thrown during load and unload, ground of storage area must also cleaned from in stacking of coils, the height of coils stocked upwards must not exceed 1 .5 m. Straight pipes may be stored in ways.

Pyramid Storage:

5 X 10 woods are paved on the ground with i m intervals. Pipes are stored as Pyramid, decreasing by one in each row, not exceeding 1 .5 m of height. Side supports must be used to prevent pipes from sliding.

5 X 10 woods are paved on the ground with i m intervals. Pipes are stored as Pyramid, decreasing by one in each row, not exceeding 1 .5 m of height. Side supports must be used to prevent pipes from sliding.

General:

UPVC pipes do not fracture under load but are rather liable to deformation, the extent of this deformation depends largely upon the compaction of the immediate surrounding fill.

The external backfill and surcharge loads imposed on a pipe of rigid material. (Such as vitrified cloy, concrete, asbestos cement or cast iron) are supported mainly by the resistance of the pipe to circumferential bending.

On the other hand, UPVC pipes, being relatively flexible, offer less resistance to circumferential deformation and rely partly on external support to resist deformation. Therefore it sis of primary importance for UPVC pipes that fill material, particularly the bedding and side fill, should be properly compacted in order to prevent excessive deformation.

It is desirable that vertical deformation should be limited to 5% on completion of the backfilling, which can only be achieved by proper composition and compaction of the backfill.

It is essential to ovoid high stress concentrations and sharp objects such as large stones or flints which should not be allowed to come into contact with the surface of the pipe.

The flexible nature of UPVC pipes helps them to accommodate deformations resulting from ground movement or from other differential settlement under normal circumstances.

When a vertical load is imposed on the UPVC pipes the resulting horizontal force is transmitted to undisturbed trench wall by the side fill. Any deflection of the pipe will cease when the horizontal reaction of the side fill corresponds to the transmitted vertical load and estate of equilibrium is reached.

Except in special circumstances, e.g. at very shallow cover depths or where it is necessary to safeguard the foundations of existing structures, the use of concrete for bedding or surrounding the pipes is unnecessary.